歡迎光臨江陰市昌盛藥化機(jī)械有限公司

![]() 收藏本站

收藏本站

![]() 聯(lián)系我們

聯(lián)系我們

歡迎光臨江陰市昌盛藥化機(jī)械有限公司

![]() 收藏本站

收藏本站

![]() 聯(lián)系我們

聯(lián)系我們

工作原理:

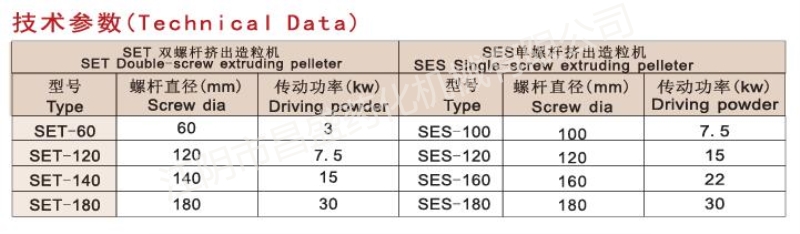

SE系列螺桿擠出造粒機(jī)分單螺桿(SES)和雙螺桿(SET)型,擠出形式有前出料和側(cè)出料兩種。經(jīng)混合、捏和的濕物料或軟化點(diǎn)(一般指小于50℃)物料在螺桿輸送、擠壓作用下,從機(jī)頭開(kāi)孔模板擠出,再經(jīng)過(guò)干燥或冷卻得到顆粒成品,從而實(shí)現(xiàn)將粉狀產(chǎn)品改變?yōu)榫鶆虻念w粒產(chǎn)品的目的。顆粒形狀為圓柱狀,成品顆粒直徑可由模板開(kāi)孔孔徑調(diào)節(jié)和控制;側(cè)出料為0.7-3.0mm,前出料為1.5-12mm,成粒率≥95%

Working Method:

SE series of screw type extruding pelleter in clued single-screw type and double-screw-type. Two models of front and side for material to be extrudedWET material or material with low melting point (general means <50C0) after being kneaded and mixed shall be extruded out from mould plate at the head of the plant due to being conveied and pressed by screws, and then be dried or cooled to from end products of particles so as to complete the course of Changing material from powder to particle. The shaoe of grain is cylindrical. The dia of end grain can be choosed and controlled by means of changing the dia of holes in the mould plate: for side type is 0.7-3.0mm,for front type is 1.5-12mm.The rate of end product is equal to or more than 95%.

應(yīng)用范圍:

廣泛適用于橡膠助劑、食品添加劑、塑料助劑、催化劑、農(nóng)藥、燃料、顏料、日化、制藥等行業(yè)需造粒的產(chǎn)品。

Applied scope:

The plant is widely applied to material needs granulating such as Rubber auxiliary , Food Additive Plastic Auxiliary , Catalyzer, Agrochemicals, Dye, Pigment, daily chemicals, medicine etc .

江陰昌盛藥化機(jī)械有限公司(江陰市昌盛制藥機(jī)械廠(chǎng)),位于江陰市文林鎮(zhèn),東連上海、南臨蘇州、無(wú)錫,地處“黃金通道”之稱(chēng)的滬寧高速公路無(wú)錫東。本公司主營(yíng)干燥機(jī),混合機(jī),制粒機(jī),粉碎機(jī)等藥化設(shè)備。本公司有三十年的機(jī)械制造歷史、技術(shù)力量雄厚、工藝先進(jìn)、設(shè)備齊全、由于生產(chǎn)及市場(chǎng)需要,本公司聘請(qǐng)了制藥、化工、食品機(jī)械方面的多名專(zhuān)家及工程技術(shù)人員,發(fā)展了一系列的制藥及化工機(jī)械設(shè)備,主要產(chǎn)品有中藥粉碎機(jī)、篩粉機(jī)、混合機(jī)、制粒機(jī)、干燥機(jī)等多種系列產(chǎn)品,為我國(guó)的制藥及化工、食品等行業(yè)的機(jī)械裝備更新?lián)Q代作出了一定的貢獻(xiàn)!產(chǎn)品質(zhì)量得到廣大用戶(hù)的一致好評(píng)。